A shelf unit is a piece of furniture consisting of several shelves combined into a single structure. Shelf units can be made from wood or metal, with open shelves on all sides or partially closed.

Advantages of Making Your Own

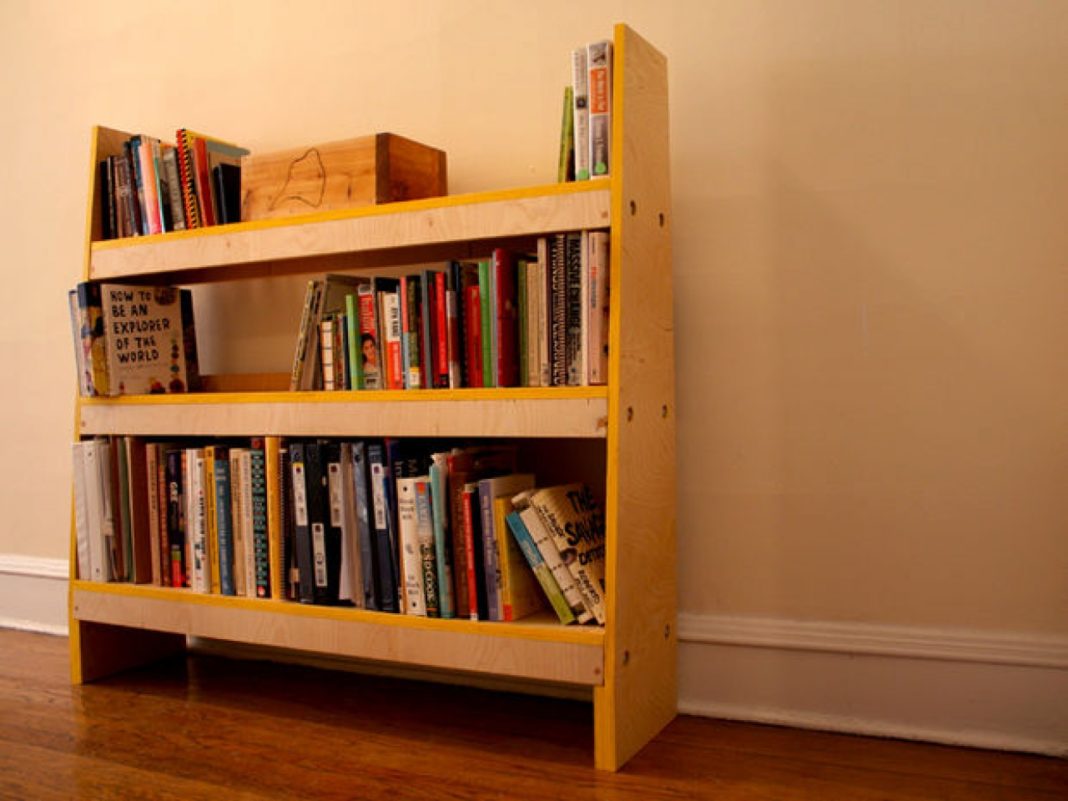

Wooden Shelf Unit

When creating furniture yourself, including shelf units, the advantages compared to industrially produced samples are:

- The cost of self-made items is significantly lower than buying ready-made analogs.

- The ability to create furniture in an individual style that matches the design ideas of the room or other space where it is intended to be placed.

- The quality of the manufactured furniture is controlled by the maker, ensuring successful operation for a long time.

- The person making the furniture enjoys the work and can be proud of the result.

- The person gains new skills that will be useful in the future.

- Making furniture can be a business that provides a certain income to the producer of such items.

Necessary Tools and Materials

Lumber

To make a wooden shelf unit yourself, you will need:

- Materials

For making shelves and the frame of the shelf unit, you can use planed boards of various wood species (pine, spruce, birch, oak, aspen, etc.), as well as sheet materials made from wood processing waste (particle board, plywood, OSB boards).

- Tools

For making blanks and assembling the structure, you will need: a circular saw, an electric jigsaw or saw, a set of chisels and carpentry tools, clamps, a plane, fastening elements, and carpentry glue.

For finishing the assembled shelf unit – paint brushes, varnish, paints, as well as special tools and substances that allow you to give the structure an “antique” look, if necessary.

Construction and Connections

The construction of the shelf unit depends on its area of use, the imagination of the developer, and the type of materials used.

This can be a shelf unit for books or shoe storage, for placing flower pots or children’s toys, as well as for storing other items.

When using sheet material as shelves, the frame of the shelf unit is made from solid wood, and the connection can be made in the form of a saw cut or using fastening elements (angles and plates), as well as the “overlap” method.

The “overlap” method is characterized by the fact that the shelves are not placed directly on the vertical posts but are mounted on horizontally arranged elements of the frame.

If the frame is made from particle board, plywood, or similar material, then the connection is made only by using fastening elements.

The construction of the shelves can also vary, depending on the area of use of the shelf unit, such as: flat shelves, used for storing various items and things, box-type – used for planting flowers and plants.

Shelves can be arranged in one vertical plane or offset relative to each other.

Stand-type shelf units are assembled by installing special tenons with subsequent gluing of the joints of the structure elements.

Modular shelf units can have different constructions, which depend on the material used in their manufacture. Usually, this is sheet material, assembled using fastening elements.

How to Make a Wooden Shelf Unit Yourself

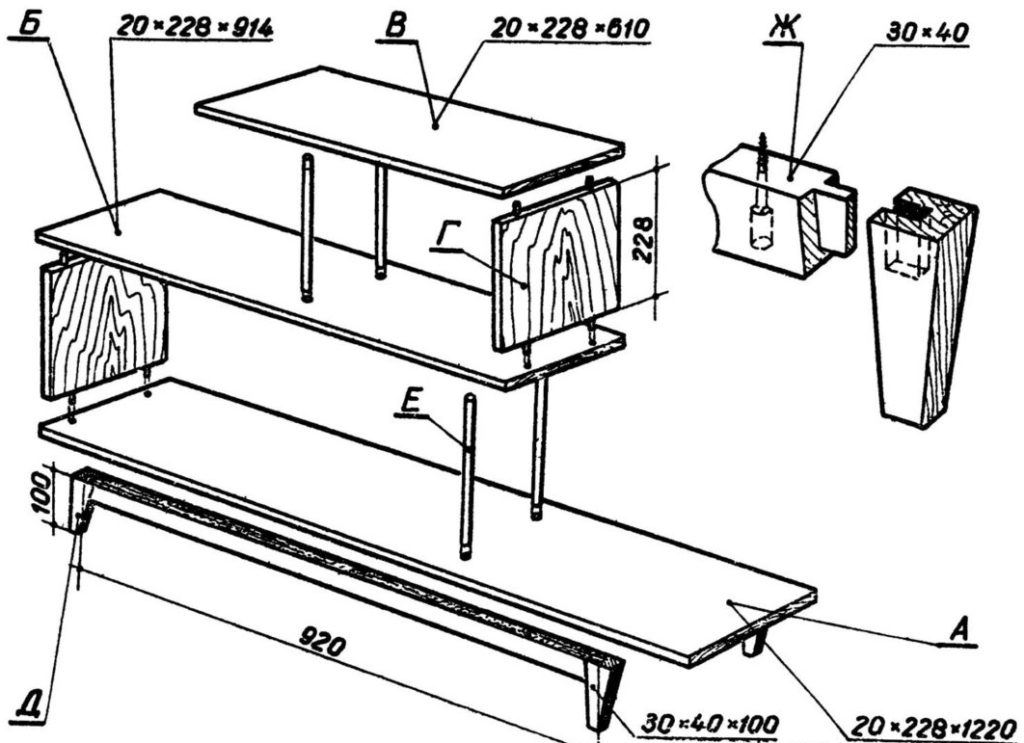

Shelf Unit Drawing

The work of making a wooden shelf unit yourself can be divided into several stages: preparatory, assembly, decoration, and installation.

Preparatory Stage

At this stage of work, a drawing (scheme) of the shelf unit is selected or developed, and the need for its decoration is determined.

Based on these parameters, the required material is selected.

When the drawing is developed, the material is selected and prepared, and the preparation of tools and other materials that will be needed for processing the assembled structure is carried out.

Assembly of the Shelf Unit

Using the prepared material and tools, the blanks are made and processed.

Blanks are sawn according to the available drawing or sketch, after which the sawing places are cleaned to remove irregularities in these places. When using boards – they are planed with a plane and sanded.

The assembly of the shelf unit is carried out.

The variants of fastening the blanks to each other depend on the material used and should ensure the required rigidity of the structure.

Methods and places of installation of fastening elements should be thought out at the stage of developing the sketch of the product.

Decoration of the Structure

The simplest option for finishing the assembled product is to cover it with varnish or paint. This applies to both lumber of various types, as well as plywood and OSB boards. When using particle board, only the edges need to be processed, for which edge material is used, glued to these parts of the structure.

When using lumber and striving to make the shelf unit “antique,” several processing methods can be used:

- Brushing – a method where mechanical processing of wooden products with metal brushes is carried out, followed by their polishing and processing with wax-containing substances.

- Using stains with which the manufactured product is processed.

- Patination – a method where the wooden surface is painted with paints of various shades in several layers.

- Craquelure – a method of processing painted surfaces with a special composition, craquelure, which gives the product an “antique” look.

Installation of the Product

After the shelf unit is made and decorated, it is installed in the intended location.

Depending on the purpose, the shelf unit can be securely attached to the surface of the wall or floor, as well as freely placed relative to them.

The fastening option depends on the material that was used in the manufacture of the shelf unit and the construction of the walls and floor in the room where it is installed.

Currently, thanks to the availability of the internet, you can always find drawings of any furniture, including shelf units of various constructions, which can be used in their independent manufacture. And the variety of materials and technologies – allows you to bring to life any creative ideas.