Insulating the ceiling in a wooden house is an integral part of the work aimed at maintaining a comfortable temperature. Insulation can be done both from the roof side and from inside the house. It is most reasonable to insulate the ceiling during construction or before finishing the house. Make independent insulation of the ceiling in a private building is not easy, but to choose the right option for the work – the main task of each owner. The technology of insulating the wooden ceiling will depend on the material purchased for this purpose.

Mineral wool

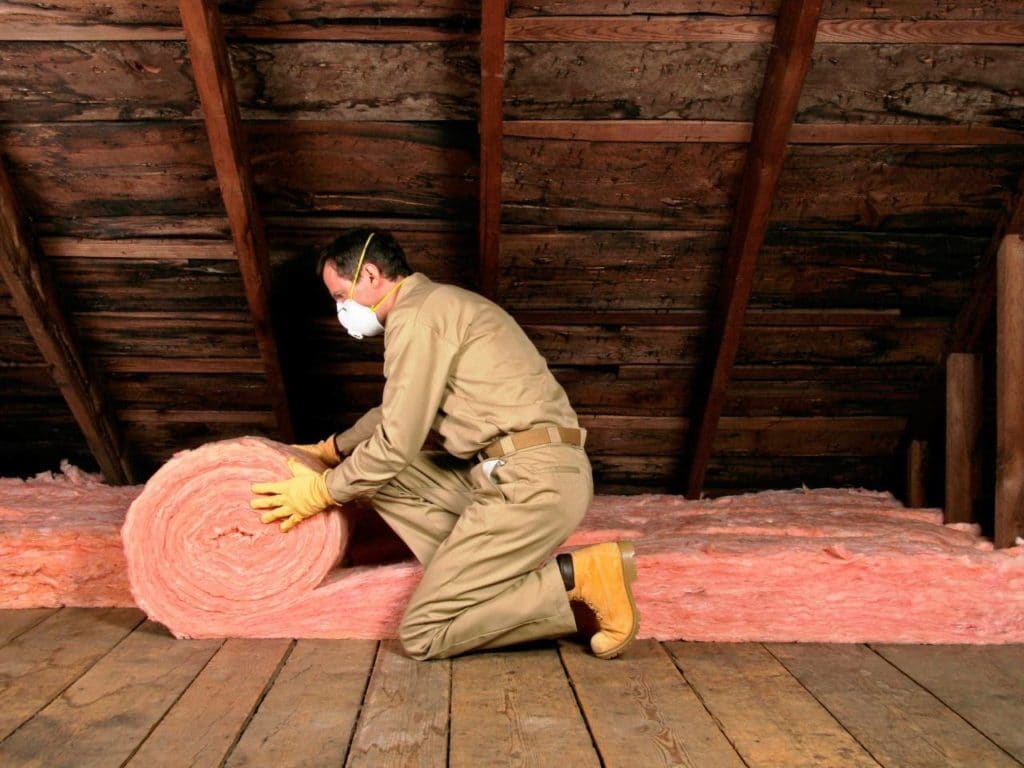

A type of insulation material, where the fibers are arranged chaotically, so that between them there is an air cushion, perfectly retaining heat. However, this feature has a negative side – wool absorbs moisture. To avoid this, you need to understand how to insulate the ceiling in a wooden house minwata. In addition to excellent heat retention, mineral wool has other advantages:

- long service life;

- easy to work with;

- possibility to insulate any surface.

Stages of insulation

There are 3 ways of laying the material: flat, in grooves and in cells. The choice of one of them depends on the loads that will be experienced by the structure.

The whole process should be divided into the following steps:

- Work on insulation of the ceiling in a wooden house with their own hands should begin with the laying of a vapor barrier film. It is required to withdraw moisture rising from the rooms to the attic. To qualitatively fix the film, it is necessary to study the indicators of its labeling. When installation is carried out on wooden beams, the film must necessarily envelope each of the protruding elements, otherwise the wood will rot. At the joints of protruding surfaces, it is necessary to make an allowance identical to the thickness of the insulation, and finally glued with tape.

- Laying insulation – an uncomplicated occupation, it can easily be carried out without helpers. Slabs and strips of material are cut according to the necessary dimensions. When laying it is necessary to make sure that there are no gaps between the strips of insulation. Also min. wool should not be squeezed, as this will affect the quality of the insulated ceiling.

- If the attic room will not be used for household needs and the rafters are not protected by anything, then it is necessary to lay the waterproofing. If the roofing material is separated from the attic by a film, it is necessary to proceed to the last stage of work. The rough floor is laid on top of the insulation, it will be the basis for the final finishing.

The following must be kept in mind:

- Insulation material with foil increases resistance to cold air. The foil layer should be placed at the bottom when laying min. wool.

- Mineral wool should not protrude beyond the beam. It is necessary to use an extension strip if there is a mistake in calculations.

- Thin mineral wool laid in two layers will increase thermal insulation. It will more reliably retain heat than one thick insulation, but it should be staggered.

- If there are protruding elements in the attic, it is recommended to raise the insulation by 35-40 cm, and then fix it.

Foam insulation

Insulation of the ceiling in a wooden house foam plastic on the principle of installation is practically no different from the work with other similar materials, for example, polystyrene foam.

The advantages of such insulation are as follows:

- low price

- ease of installation

- water resistance.

Among the negative sides

- high combustibility

- fragility

The process of laying rigid insulation is much simpler than other options, and can be easily performed without prior preparation and additional knowledge.

Installation can be divided into 2 stages:

- leveling of the surface. To guarantee quality insulation, the surface should not have any irregularities.

- Surface imperfections can be eliminated with the help of cement mortar screed.

- The boards are installed butt-to-butt or the elements are laid between the joists.

- The presence of a bar strengthens the strength of the construction.

In the process of foam plastic laying, try to avoid gaps between the boards and carefully seal each seam, joint with the beam, etc., to avoid gaps between the boards. Styrofoam is fragile. To protect it from destruction, a rough floor is laid on top of it in the living attic. It is usually made of OSB boards or cement screed is used.

Керамзит для утепления потолка

Claydite – insulation material, which is obtained by firing clay. Ceiling insulation with expanded clay has the following positive sides:

- availability;

- lightness;

- environmental friendliness;

- weak thermal conductivity.

The disadvantage of this material is associated with lifting expanded clay to a height. Since it is made in the form of granules of different sizes, sometimes its lifting to the attic of a private house is associated with difficulties. Usually insulation with expanded clay is used in cases where it is necessary to insulate the attic on the slabs.

Insulation technology

Insulating works with expanded clay are carried out in 3 stages:

- The slab is carefully inspected, gaps and cracks are identified, which are sealed with cement mortar or covered with thin cardboard. Protruding surfaces do not create difficulties during the laying of expanded clay, and they are not paid attention to.

- 2. Make a batten from a wooden bar, on which further will lay the rough floor.

- 3. Granulated insulation material is poured onto the slab, after which the surface is leveled with an ordinary garden rake.

The thickness of the insulation layer should be at least 4-5 cm. You can move over the expanded clay without any restrictions, the quality of the surface will not be affected.

It is desirable to use granules of different sizes in the process of insulation works. In this way it will be possible to avoid the occurrence of voids in the insulation. At the end of the work, a rough floor is laid or a cement screed is poured, which will get rid of voids and strengthen the insulation layer.

Sawdust for ceiling insulation

Sawdust is the waste left after wood processing. This type of insulation has the following positive aspects:

- availability of the material;

- no chemical composition;

- low weight of the insulation.

But, just like other budget options for insulating living spaces, sawdust is not without negative sides.

The disadvantage of the material is its property of being easily flammable.

Sawdust insulation

Before you start insulating the room with sawdust, they need to be prepared. To do this, they should be mixed with water and cement in the proportion of 10:1:1. The resulting mixture should be poured over the surface of the attic floor and well level it. Apply the mass of sawdust without building a frame is recommended only in non-residential premises. If frameless insulation with sawdust will be used in a residential house, it will lead to pressing of insulation material, as a result of which the insulation of the room will be less qualitative.

Therefore, before you start insulation, it is desirable to build a cellular frame from a bar. The prepared mixture is poured into each cell. The positive side of this method is that after sawdust on the frame it will be possible to lay the rough floor and the attic room will become suitable for creating a living room.

The process of insulating the ceiling in a private house has some peculiarities that need to be taken into account during installation. Wood is quickly subjected to rotting, so the steam that will rise should pass unobstructed through the ceiling, so the installation of non-breathable materials is recommended to be excluded. When using foil-based insulation, it is necessary to place the foil side from the bottom. In this case, the timber and boards will be reliably protected from water and moisture will not be able to accumulate in them.