A well is a technical structure used for extracting water. The well’s design includes a mechanism for lifting water from the ground surface and a protective enclosure for the excavation from which groundwater is extracted.

The well, its excavation, and external framing can be made from various materials, allowing the well house to be designed in different styles. Anyone with free time and a desire to have an original, individually styled technical structure on their property can build a wooden well.

Planning the Well Location

Planning the Well Location

The location of the well on the property is determined based on the presence and depth of groundwater, as well as the presence of springs in the area.

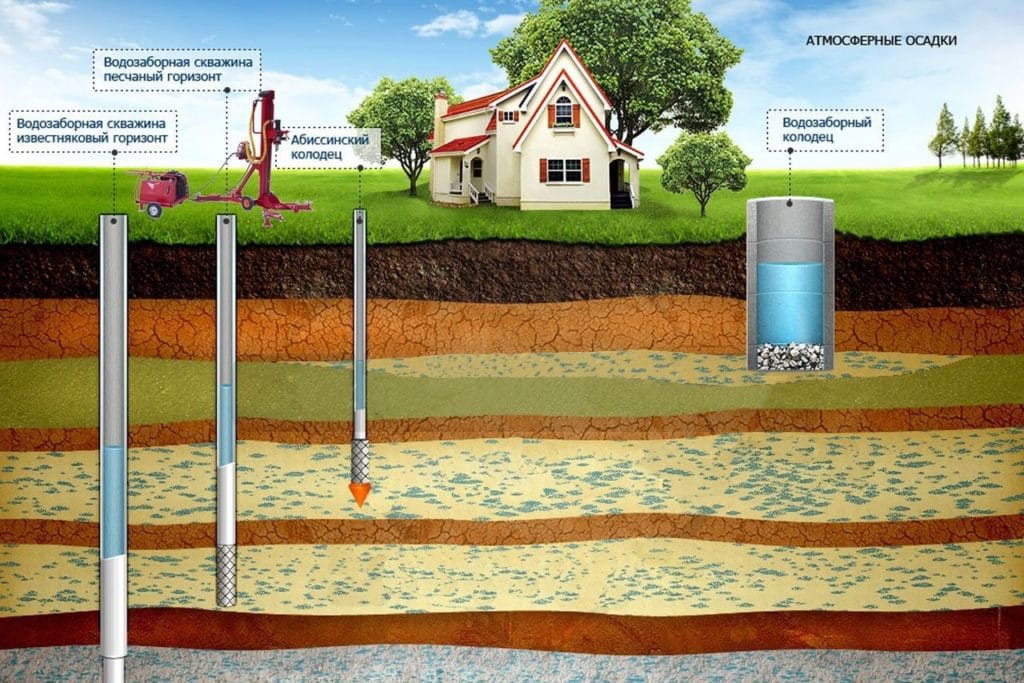

Groundwater, according to its type, is classified as:

- Surface water – characterized by shallow depth and is replenished by precipitation, snowmelt, and floods. It has a low degree of purification, requiring additional water treatment systems.

- Groundwater – located in the water-bearing layer of the earth and has a certain reserve of water. There is no pressure in the water-bearing layer, and the water level in the well corresponds to the level of the water-bearing layer. The degree of water purification is higher than that of surface water.

- Artesian – located deeper and usually between layers of rock. When using this type of water for a water supply system, the water flows under pressure formed in the water-bearing layer.

To determine the exact location of the well, it is necessary to gather information about the presence and nature of groundwater and consult specialists in hydrology or use folk methods.

Specialists can use hydrological maps or perform necessary drilling work (exploratory drilling), which will allow for the creation of a scheme of hydrological layers in the earth’s surface.

Folk methods involve using metal wires or wooden sticks to determine where groundwater is closest to the surface. It should be noted that folk methods provide an approximate location, and the exact location can only be determined using technical methods of examination.

Additionally, there are norms regulating the location of the well relative to other buildings and structures, which are reflected in SNiP 3.05.04-85* “External networks and structures of water supply and sewerage (with Amendments).”

Choosing the Wood

Birch for the Well

When using wood to construct a well, various types of raw materials can be used, such as oak, birch, aspen, pine, or spruce.

The choice of wood is based on its ability to withstand moisture when framing the well and the effects of sunlight and microorganisms when constructing the above-ground part of the well.

Typically, the log structure is made from oak, aspen, larch, elm, or alder, due to these species’ ability not to rot when submerged in water for extended periods.

For constructing the well house, the above-mentioned wood species, as well as others like spruce, pine, and birch, can be used.

Materials and Tools

When constructing the log structure, timber, half-timber, or round wood is used, and for building the well house, planed boards of various thicknesses are used.

The taste of the water drawn from the well largely depends on the type of wood used for the log structure, as well as its quality and ability to resist rotting.

For finishing the exterior of the well, paint or varnish, as well as other finishing materials, will be required, depending on the style of the well house.

To build a wooden well yourself, the following tools are needed:

- Chainsaw, two-handed or bow saw.

- Axe.

- Handsaw.

- Plane.

- Carpentry tools.

Types of Wells

Tubular Well Construction

Wells differ in the type of excavation from which water is extracted. They can be of the following types:

- Shaft wells – constructed by digging a shaft. The work is done manually using shovels and other hand tools.

- Tubular wells – constructed mechanically (drilling or punching), followed by the installation of a well.

Additionally, wells can be classified by the type of water intake structure through which water enters the internal space of the shaft (well), including:

- Full immersion – water enters through the side walls, and the bottom is mounted on a waterproof layer.

- Incomplete – water enters through the side walls and the bottom of the well or shaft.

- Perfect with a sump – a reservoir is installed in the water-bearing layer, serving as a water collector, into which the well structure (shaft, well) is immersed.

- With an expanded underwater part, serving for water accumulation.

How to Build a Wooden Well

Before starting the construction of the well, it is necessary to perform a series of preparatory activities, which include:

- Determining the location of the well.

- Calculating the daily water requirement, both for cooking and technical purposes.

- Choosing the type and design of the well.

- Selecting and purchasing the material required for construction.

- Preparing the tools.

Once the preparatory activities are completed, it is necessary to plan the work technology.

The technology should ensure the completion of work in the shortest possible time, with minimal labor costs, and ensuring the safety of the work.

Log Structure Assembly

The manufacture and assembly of the log structure are carried out on the ground surface. The connection of the logs is made in the form of “lap joint,” “cup joint,” or with other types of locks (“hook joint,” Finnish, Swedish, or Norwegian lock), and when using timber – “with remainder,” “without remainder,” “straight tenon,” “corner tenon,” or “dovetail.”

The size of the log structure, its height, depends on the depth of the groundwater and the required height of the structure rising above the ground surface.

The side of the log structure typically measures 1.0 meters but can be larger or smaller, depending on the personal preferences of the builder and the structures located near the well being constructed.

During the assembly of the log structure, rows are installed with wooden dowels, ensuring the rigidity and strength of the structure.

The manufactured log structure is marked to facilitate further assembly in the well shaft.

How to Install the Well

Well Installation

There are several technologies for installing a shaft-type well using a wooden log structure, which determine the possibility of performing such work with different groundwater levels.

The installation can be carried out in the following ways:

- Gradual assembly.

In this method, a pit (shaft) is dug, at the bottom of which the manufactured log structure is assembled. This construction method is suitable for shallow groundwater, dense soil, and the absence of water supply from the side layers of this soil.

- Submersible construction.

This method is used for deep groundwater. Initially, a pit is dug to a depth of 5.0 – 6.0 meters, into which the manufactured log structure is installed, after which the soil is removed from under the lower wreaths of the log structure. As the structure is submerged, the wreaths located in the upper part of the log structure are installed.

- Adding wreaths from below.

This technology is used for the construction of deep wells. The peculiarity of this method is that the wreaths are added from below to the installed log structure.

The installation of the log structure is carried out in the following sequence: a pit is dug to the maximum allowable depth, after which the log structure is assembled, with its assembly height determined by the depth of the dug shaft.

The installation of the wreaths is carried out in such a way that the upper rows of the manufactured log structure are located in the required plane above the ground surface.

The lower wreaths are laid on pads, after which the soil is removed both in the vertical plane (deepening the bottom of the well) and in the horizontal plane.

The removal of soil in the horizontal plane is necessary to allow the installation of supports or jacks, ensuring the suspension of the assembled structure.

When the log structure is suspended and the required amount of soil is removed, the next wreath (or several wreaths) is installed, after which the supports (jacks) are removed, and the installed rows are secured to the previously installed ones.

After the installation of the log structure, backfilling and compaction of the soil from the outer side, as well as the construction and finishing of the well house, are carried out.

Safety Rules During Well Digging

To prevent accidents and ensure safety during well digging, the following safety rules must be observed:

- The area where earthwork is being performed must be fenced off, for which a fence or other enclosing structures are installed.

The earthwork area is fenced off around its perimeter, at a distance of at least 1.0 meters from the work being performed.

- There should be no heavy objects or structures in the work area that could fall into the pit (shaft) during construction.

- Proper tools and personal protective equipment must be used during the work.

- Ropes or cables used during the work must be checked for strength.

- When using devices with electric drives, they must be equipped with automatic stop or braking devices.

A well is a fairly complex technical structure, the construction of which is best entrusted to professionals with experience in performing such work. However, with the desire and observance of safety requirements, as well as possessing certain knowledge, anyone can build a well on their own.