A properly equipped work area for carpentry or metalwork should be comfortable and functional. It is possible to build a central piece – a wooden workbench – using individual drawings.

- Characteristics of the Construction

- Main Requirements and Preparatory Work

- Choosing the Construction Project

- Drawing the Plan

- Material Characteristics

- Fastening Elements

- Process of Assembling a Carpentry Workbench

- Making Parts

- Assembling the Workbench Base

- Forming the Tabletop

- Additional Equipment for the Workbench

Characteristics of the Construction

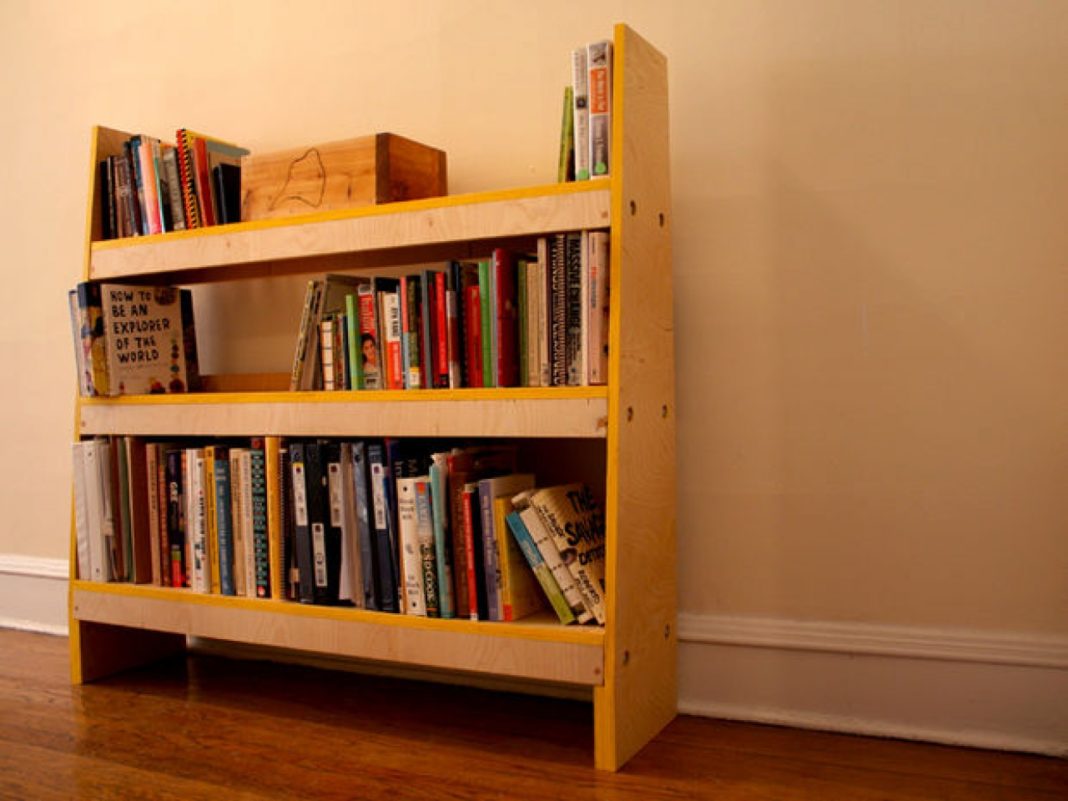

A fitter’s workbench is a special table-like structure equipped with various electromechanical devices. The surface must be highly durable to secure additional equipment. Functionality can be enhanced with drawers, shelves, and tool holders.

A wooden workbench made by hand has differences depending on its purpose: for fitting, carpentry, or metalworking equipment. The standard construction includes:

- Base or underframe;

- Tray or box lid;

- Shelves, drawers;

- Apron.

Tables can be multi-seat or single-seat. Standard dimensions for single-seat tables are 800 cm wide and 1.5 m long. Multi-seat options increase depending on the desired number of work zones.

The height of the construction is chosen individually (800-900 cm). There are also adjustable height models. The table material is wood or metal. The tabletop is finished with galvanized sheet metal, plywood, hardboard, or boards.

Main Requirements and Preparatory Work

A wooden fitter’s workbench made by hand should meet workplace and safety criteria. It is also important to determine the type of construction in advance, considering stationarity, mobility, or the possibility of disassembly.

Choosing the Construction Project

To make the work area comfortable and functional, you need to familiarize yourself with the main design aspects of the workbench. The choice of construction is strictly individual and depends on the specifics of use.

A workbench for the garage can be designed using three main options:

- Portable (mobile). This equipment is optimal for small rooms and is easily moved due to its light weight. A portable table is suitable for small jobs. Additionally, the workbench can be equipped with vices or a grinder.

- Stationary. This massive construction is designed for large-scale work (sawing). The design drawings should consider practical installation. The workbench is optimal for installation in a workshop in a private home. In a garage box, the equipment will take up too much space and rarely be used for technological operations.

- Assembly. The construction is made on bolted connections, allowing the equipment to be modified according to construction needs. The assembly process is quite labor-intensive. Vibrating device fasteners installed on such a machine require constant tightening.

When deciding to make a wooden workbench for the garage, it is recommended to choose a mobile construction project. If a stationary installation is needed, you can simply secure the table legs to the floor. The assembly construction is distinguished by durability due to the possibility of replacing damaged or loose parts.

Drawing the Plan

After choosing the project, you need to draw the future item. There are reference parameters, the use of which is not axiomatic. When making a wooden workbench, the drawings can be adjusted to the desired height and width of the tabletop. The height of the item should first correspond to the height of the craftsman.

When drawing the plans, consider additional parameters:

- Number of shelves, pedestals;

- Installation of limiters;

- Presence of clamping devices;

- Lighting fixtures.

Drawers, tool holders will make the work process more comfortable. Limiters will facilitate work with elements of different sizes. Clamping equipment (vices) will securely fix samples. Quality lighting will ensure work convenience, so it is important to think through the lighting scheme in advance.

Material Characteristics

A wooden workbench made by hand must strictly comply with generally accepted standards of strength and safety. A carpentry table is installed in technical rooms, which will require considering the temperature regime and humidity level when choosing materials.

Quality characteristics of wood should be distinguished by hardness and resistance to destruction. Even with good moisture-proofing properties, porous material will not have the necessary level of strength. It is recommended to make a wooden workbench from planed timber and boards.

The cross-section of the timber for the frame depends on the size of the construction. Compact items will require the use of material 100×70, more bulky ones – 100×100. The choice of board should correspond to thickness indicators of at least 50. It is possible to make the workbench universal, combining the possibility of carpentry and fitting work. It will be necessary to make a section of the tabletop with a sheet metal lining.

Metal can be used as the main material for manufacturing. This option is massive and heavy, suitable for stationary projects.

[wpmfc_cab_sw]The disadvantage of a metal construction is the absence of a leg opening in the table. This element negatively affects the ability of the base to withstand dynamic load.[/wpmfc_cab_sw]

Fastening Elements

A table for fitting work should have strong and reliable fastenings. Bolts are selected according to the necessary thickness, leaving space for a washer, grover, and nut. The use of nails causes a number of contradictions. This type of fastening can split the frame beam or cause verticality of the parts to be violated. Dismantling or replacing a part of the workbench can cause difficulties due to the complexity of removing a tightly driven nail.

The most reasonable use is screws. A workbench made by hand in a mobile project variant can be additionally reinforced with slats, corners, or metal plates. The necessary strength of the connection can be achieved by selecting the optimal length of the fastening leg. The width of the part should exceed the thickness of the fastened base by three times.

Process of Assembling a Carpentry Workbench

A wooden workbench made by hand requires special attention to the execution of angles during assembly. Even a slight skew or level violation will lead to the construction being crooked. During the work, it will be necessary to regularly measure the evenness of the construction joints.

Making Parts

Marking and making workbench parts should be done according to the planned drawings. Samples are subject to careful processing and sanding. It is recommended to select a special composition for wood treatment, enhancing the material’s resistance to destruction, moisture, and mold damage.

It is important not to ignore the process of drying parts. This stage cannot be artificially accelerated by heating. As a result, surface deformation may occur. Evaporation of moisture should occur naturally, with good ventilation and even temperature indicators in the room.

Assembling the Workbench Base

A workbench made by hand is assembled from the base – a load-bearing frame made of beams. The necessary strength and reliability of the construction can be achieved using the “tongue and groove” assembly option. The joint parts are additionally processed with glue. Fastening with screws and reinforcing elements will advantageously complement the assembly of the base.

Installing base parts on glue is reasonable in the closed conditions of a garage or workshop. If it is planned to use the table in unheated rooms or outdoors, glue fixation is not used, as in case of the need to replace a part of the table, the frame will need to be reassembled.

Massive constructions can be reinforced using diagonal or horizontal crossbars. Oversights in the additional rigidity of the item at the design stage can be worked out during assembly.

Forming the Tabletop

A quality work table surface should consider the need for replacement. The tabletop is most susceptible to intensive impact during fitting or carpentry work. The mobility of dismantling elements should be thought out in advance, securing the tabletop with special metal corners.

The width of the plane should exceed the size of the base, allowing the installation of additional removable equipment. The absence of an edge will make the tabletop inconvenient and limit the functionality of the surface.

The assembly process includes laying boards with the face side down. It is important to perform the work on an even surface. Then, perpendicular to the base, the elements are fastened with beams.

The installation of wooden tabletop parts should be done, ensuring maximum density, avoiding the formation of gaps. On the final stage, the face side of the tabletop is sanded and treated with impregnating pastes.

Additional Equipment for the Workbench

Having figured out how to make a workbench from wood by hand, you need to think about the necessary equipment details for the work table. The installation of additional equipment is done depending on the chosen modification of the construction.

Installing vices will require preliminary preparation of a recess. The upper part of the vices (jaws) should be located at the same level as the tabletop surface. Equipment for fixing samples for work requires strong fastening. It is reasonable to use bolts and nuts, allowing the device to be dismantled if necessary. It is recommended to place the vices, stepping back from the corner of the tabletop to avoid equipment failure.

Foresighted equipment of the workbench with stops will allow conveniently fixing parts during work. Rectangular recesses require the creation of special holes, which are cut out with a jigsaw. Installing fitting tools for carpentry work will increase the functionality of the table. Stationary power tools are fastened using screws.

Having familiarized yourself with the basics of equipping and assembling a workbench by hand, it becomes possible to develop and implement interesting ideas. By modifying and equipping the construction according to individual preferences, you can create an optimal work area option.